The donor.

This vehicle as a donor was always the dream even when building my truck. Glad it worked out this way in the end as a sedan is a much better donor for this project than the truck. I had been keeping my eye on the wrecked vehicle auctions since getting the Silver Streak back in May. They were always selling for way beyond our budget until the last auction of the year. I placed the minimum bid on the live auction and there were no other bids! Everyone must have spent it on Christmas presents. The auctioneer said the insurance company will want a lot more than that by at least 50%, so it was passed in. Then a couple of days later my wife gets a phone call from the auction house and was told if we excepted just $250 more, it was ours. :) Spooky thing is that was the exact amount we paid for the truck donor 15 years earlier. I think they just wanted to clear their books for the year and took the loss. Our gain though. :)

The truck was still in pieces and getting painted at this time, so you can see parts of the bed and its tonneau in there with it. It was very hard for me not to want to work on it, but there just wasn't the room. I did however get a replacement ABS control module and fitted it, and after programming, took it for a test drive to make sure it all checked out OK. That was the reason I believe for the accident as the dealer service noted it was faulty and needed replacing, but they negated to do it.

Much prefer the SRT8 interior over the other models in the range, so that was a plus as well. Only wish we had the leather seats instead of the cloth ones of the Core model this is. The Core version of the SRT8 loses the heavy 19 speaker stereo, console cooler, as well adaptive cruise, self levelling suspension and extra driver aids etc as it is setup for better drivers and less weight overall.

In 10 years it has only done just over 50,000 km/30,000 miles which is remarkable! The 6.4 has 470 hp, so really happy about that and why I wanted the SRT8.

Fitting all the drive train and interior etc into the little Willys is going to be some task. It is 1200mm/48" shorter in length, 175mm/7" shorter in the wheelbase, and an incredibly 500mm/19.7" narrower across the firewall! The Willys wheelbase is 113", more like the 33-34 Fords which have 112", rather than the 32's which are only 106" for reference.

So the same day that the Truck came out of the workshop fully assembled after painting, the SRT8 took its place. A lot of photos, measurements and angles etc were checked. Ideas of how to exactly do things were thought through to best utilise it for the project. Confirming things I suspected like none of the front suspension can be used as the coil/shock mounts would be poking straight though the front guards!

First video of the project.

The strip down is in full swing with all the bolt on panels removed as well as all the seats, head lining, front and rear screens etc.

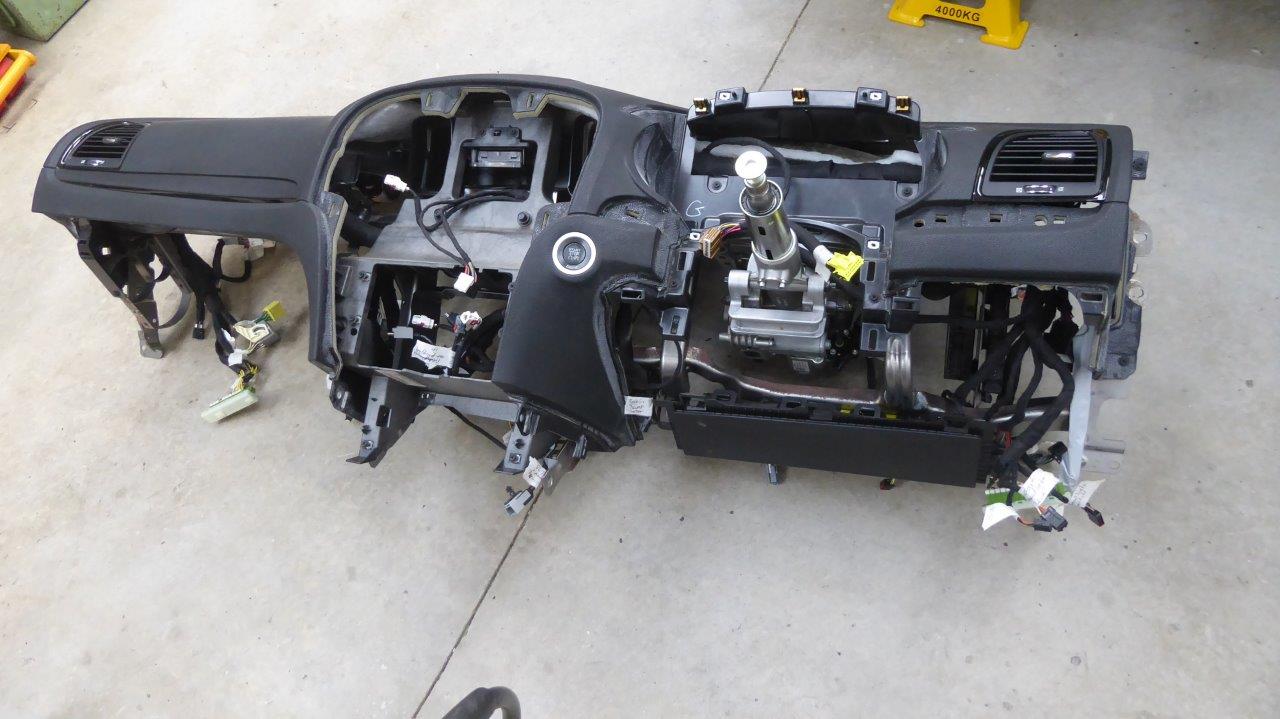

Visually I did a quick check to see just how much of the dash would be seen from under the cowl of the Willys. 3/4 of the depth would be covered as the dash actually went all the way to where the glue line of the screen was as shown by the red arrow. I have already removed the demister grill that was there.

Research showed that it is better to remove the whole dash with the frame, column, ducting and wiring etc. together. The upper half of the dash can only be removed once out to get to many of the screws holding the ducting in place between the upper and lower sections.

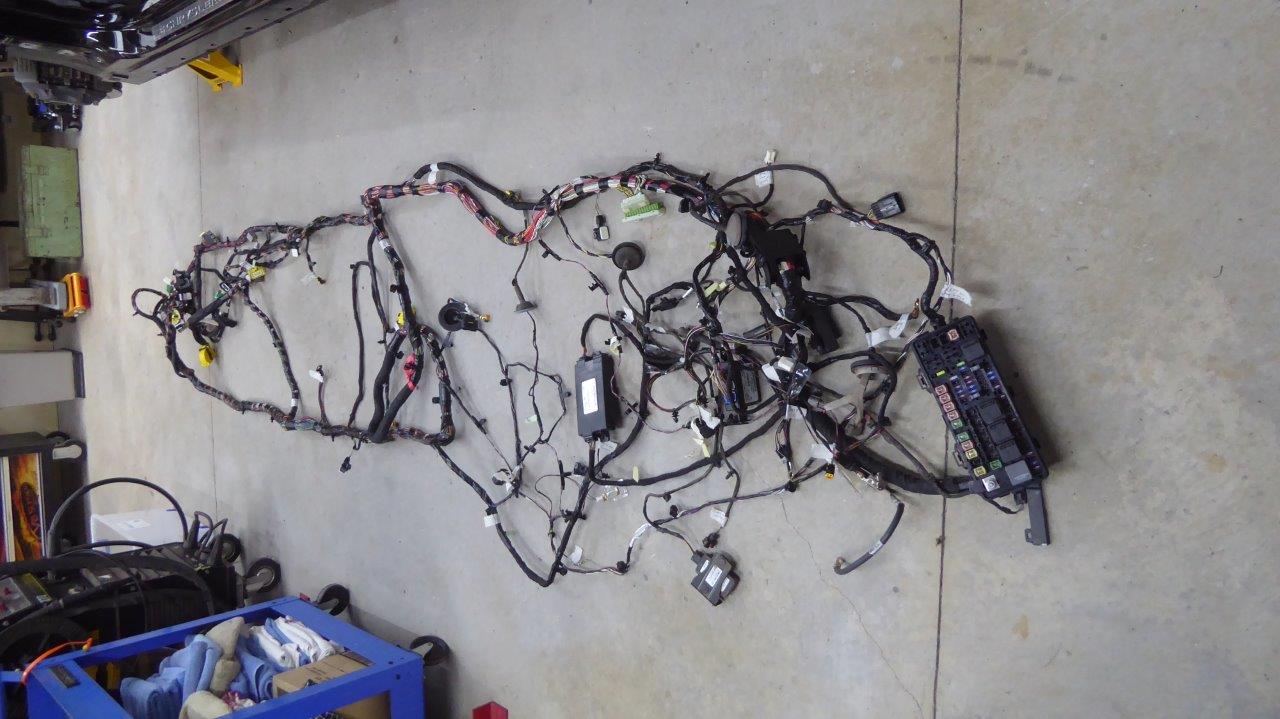

All the wiring looms from the pillars have been unclipped and laid on the floor ready to be removed with the rest of the main harness. Most cannot be unplugged from the main harness and only small sections going to the rear ABS etc unplugs.

This is all of the main cabin harness out! I have labelled everything, even the location of some like, B pillar to rear door harness etc. There is very little that runs under the floor on this model, unlike the Grand Cherokee donor for the truck which had just as much under the floor as above it.

This floor is channelled well below the top of the door sills and has a high transmission tunnel. This gives much more head room and allows the lower stance without loosing suspension travel. I really hope I can incorporate this into the Willys.

The big step up under the rear seat is where the fuel tank sits and then it steps up again for the rear independent suspension. That sits in a cradle that bolts underneath and holds the upper and lower wishbones, lower coil and shock mounts as well as the rear diff etc. All of which I plan to keep as one piece under the Willys.

So here is what it looks like with just the engine bay harness removed. This is separate from the engine harness which connects to all the sensors and injectors etc on the engine itself. I have left that in place as there is no need to remove it.

So one very full 55 litre-14.5 gallon tub with the body harness on the left and half filled engine bay harness on the right. Both harnesses will be used pretty much completely!

One of the problems I have to overcome is that the engine bay is shorter on the Willys. I really don't want to move the grille forward to fit everything in. So anything I can do to prevent that will be done.

There is a good 150mm-6" between the back of the engine and the firewall though which would be prefect if I can move it that far.

I had measured a 60mm-2.3/8" difference left to right from the axle centreline back to the firewall. There was nothing obvious in the body structure to show that much difference from the accident impact. Well now that I have started pulling the front suspension out, I see a telltale sign that all is not right with the lower control arm bushing.

I had the cut the bolt head off just to get it out. Impressed that the grade 10 bolt bent so much without breaking. Cast itself is undamaged and kept the lower control arm in place. Could easily repaired by just changing the bush if needed, but not using the front suspension anyway.