Once welded I checked for any changes that might be needed.

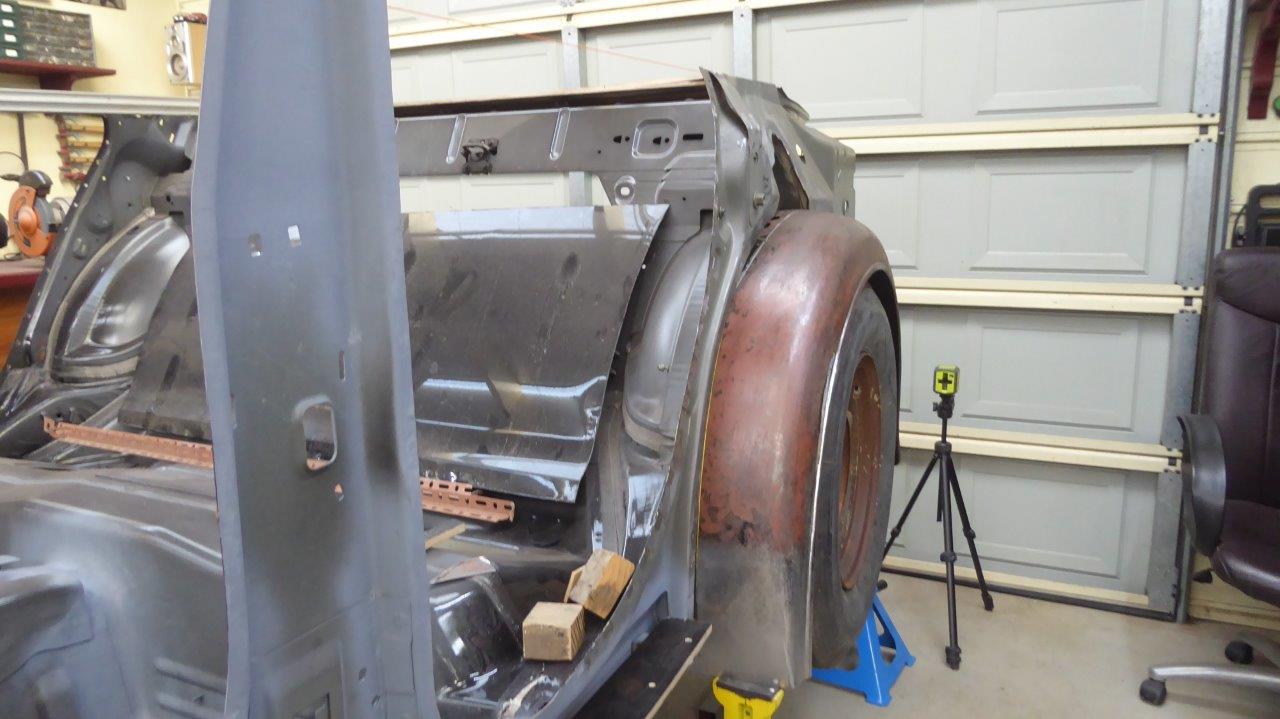

Two things I didn't like was that at the 2 o'clock position, the arch is further out from the tyre compared to the other side. The other was that the front part of the arch could be tighter to follow the tyre and then end vertical, which is needed to bolt onto the running board. As shown earlier, I had already increased the radius in a couple of spots here as was even worse before.

I took a contour reading from the less damaged guard from the other side at the top centre. Placing the gauge at the same spot on this one showed the difference between them. If you rock the gauge back it would show how the front face is more vertical than the other side. Remember that this side was stretched out 50mm-2" more than that side too and was really hard to get into place in the wheel arch. I have already brought that back so it matches once installed, but could do with more in the relaxed state.

So with more time in the English Wheel, I now have matched the contour.

I have actually started to keep this contour right around the edge as it showed it was tightening up the arch radius when doing so. The light line shows some more still needs to be done toward the right side in the picture, so back in the English Wheel it goes.

What a difference that has made! Pulling up the edge with the new contour evened out the radius and it follows the tyre with better flow. Just a little more at the start to get it right for meeting the running board and it should be good to go.

Can see the transition needs some work which will solve the last problem.

Rear view I am happy with as well. Just a slight tidy up with the blend into the reverse curve to go.

Video update.

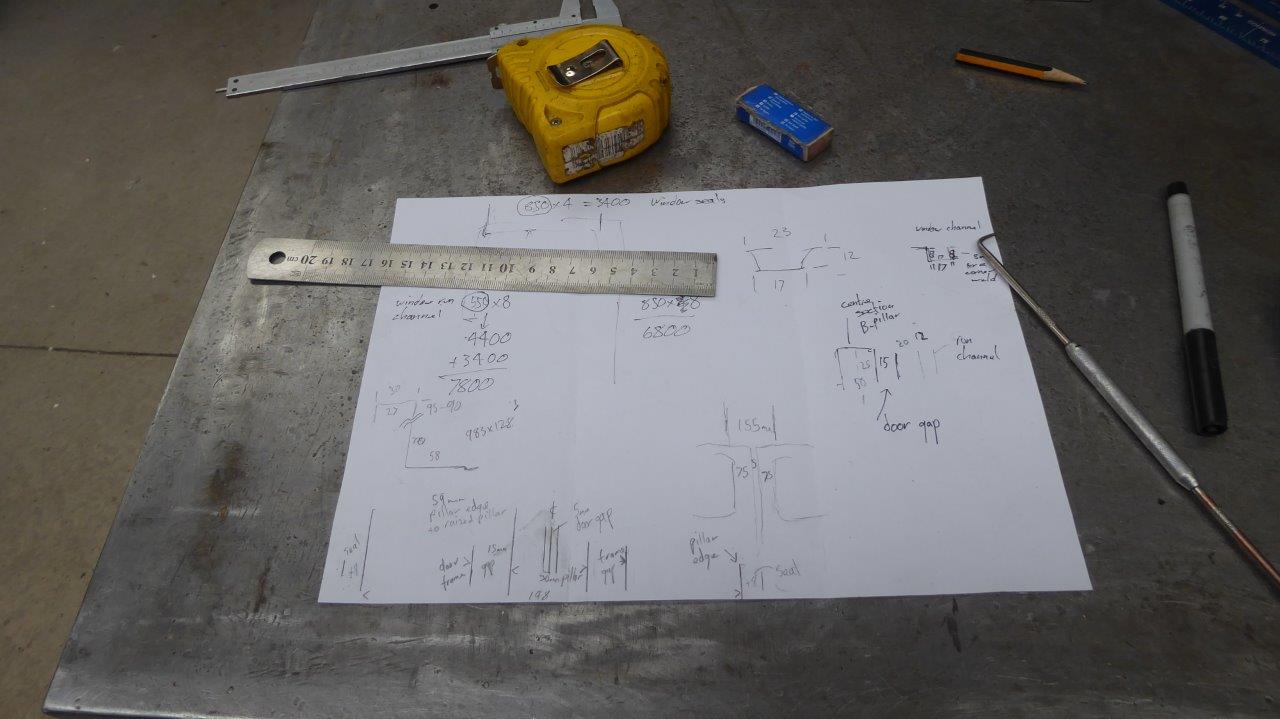

So much working out, so little to show! This is some of the notes made while working out just the B pillar. I had to see if everything would fit in the width I had between the front and rear door window frames. So that is from one window opening edge to the other one on the second door. Remembering that the rear door is suicide which places both door locks on this pillar. I added the two window frame widths, plus the door gap and then had to work out what had to fit within that space.

So the door lock width was measured along with the depth of the window run channel. Then allowance for the door frame and reinforcement plate for the lock. Then a gap between the door frame and the lock striker. From there a flange for the door skin to roll over and the gap between the doors and still have enough structural strength left in the B pillar!

By the time all that was added up it didn't leave enough strength in the centre section for where the door strikers mount. So I thought about what could be made narrower. I found some run channel that was much shallower, so bought enough to do all fours doors. I don't want to build it to something that might not be in production later on. I folded up a test piece to make sure I could produce the steel channel that the glass run channel sits in. In the end I only have to widen each window frame 5mm-3/16" extra.

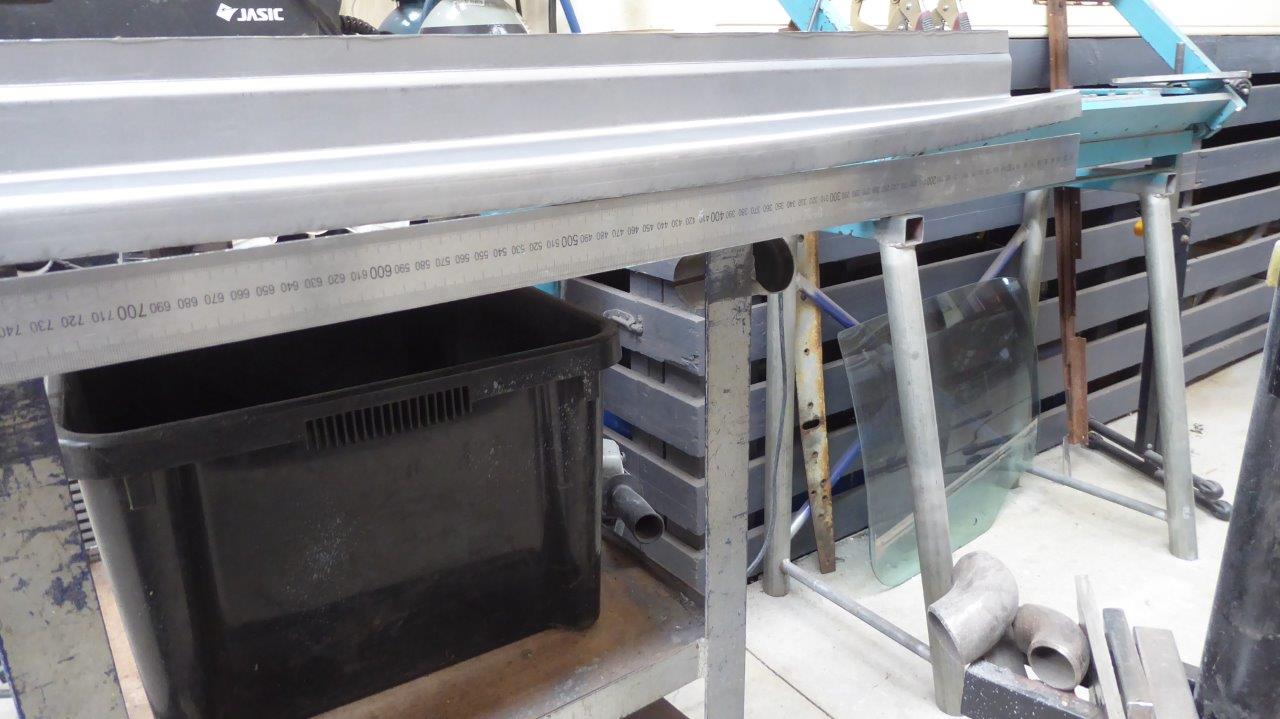

So with the depth from the B pillar edge to where the strikers have to mount worked out, I could finally start making something. To give a neater appearance, I also worked out the thickness and depth of the pinch weld rubber seal and rolled in a step so that it sits flush once mounted. I made the first piece as long as I could before it starts to curve down towards the door sill.

This piece then has the be folded 90° towards the next half. This fold has to match the exact profile of the body, so my vertical body template was clamped on to give me the shape.

Each pillar has been mapped out on the template on where it needs to sit against the horizontal template already mounted at bottom of the future door sill. This is because the window sill is angled at 2.5°, up from the Willys original 0.5°. This is also the slope of the top of the doors as the window height is the same along the car.

The next half was then made the same way. The wider lower section is what was factory on the donor car so the seat belt reel can be recessed into the bottom of it. You can see the hole it fits into on the opposite side. The step for the pinch weld seal can be seen a bit clearer here.

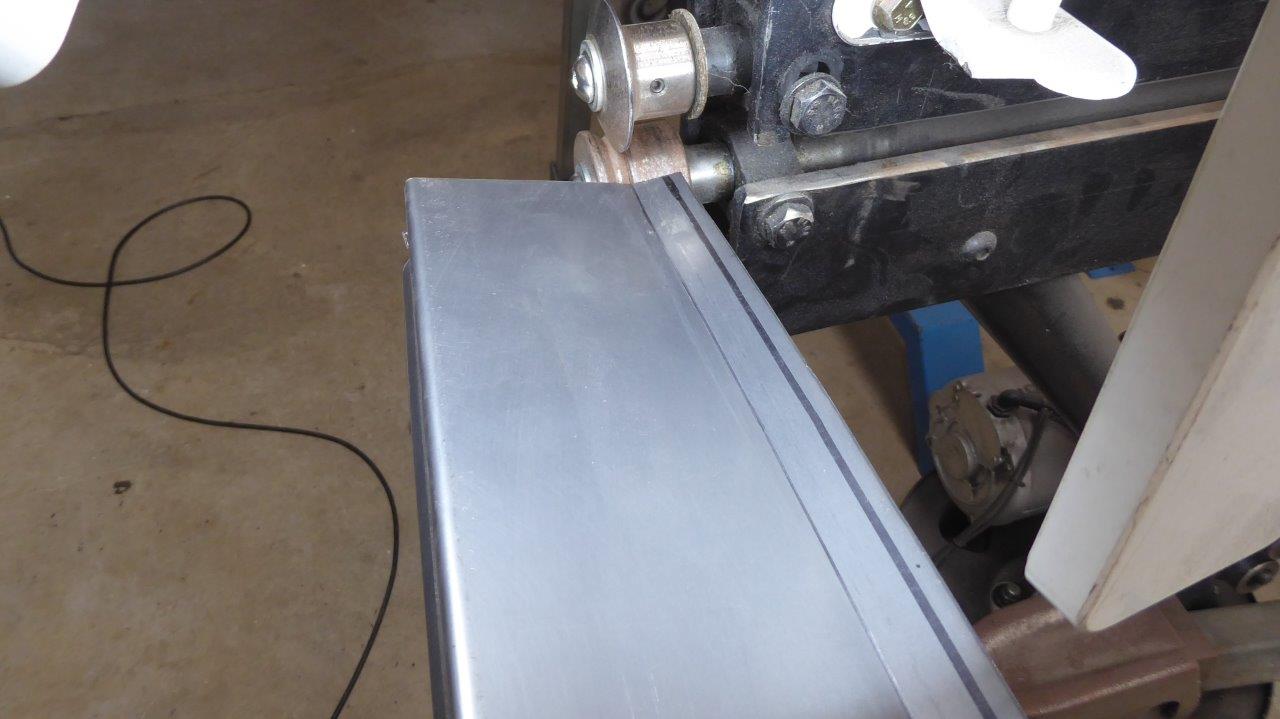

The black line is from the body template and represents the outside of the body. I then had to deduct the thickness of the door frame flange and twice the door skin thickness after it folds around it. Then also know what type of outer door seal I going to use between the inside of the door flange and the B pillar and how much the chosen seal needs to compress. The template was then moved in that total amount, plus the thickness of the B pillar itself, as the line is on the inside of the fold. As this fold is curved to match the body profile, it cannot be folded in a straight line, so the tipping wheel on the bead roller was used. First pass with the V groove under it to help start the fold. Then more passes with the bottom die turned around so you don't get a V shaped groove rather than a single fold line. The metal is pulled up while feeding it through the roller to make it bend.

I finished off the bend further by passing the pillar through the English Wheel while pushing down on it with a flat bottom die. I just find it quicker and easier than using the bead roller for the same step. You can't get a full 90° with either method, so the last part is finished off by hand.

As the fold is made on a curve, it will cause the straight side to bend some as well. The direction it will pull the metal depends on if it is inside or outside curve.

The edge of the pillar was shrunk to bring the straight side flat again.

I clamped the two halves together for the first time and it all lined up really well with each other!

I TIG welded the two halves together making only a single stop to reposition myself. I tried out a TIG pen wire feeder for the first time. Was surprised how well it worked as my XXL gloved hands have trouble feeding the 1.2mm-0.045 MIG wire into the weld pool. I looked for an all metal one of decent size and this was the Sonnler brand I bought off AliExpress.

I liked the double O-rings it uses for gripping the wire as not all of them have this. I found it good for my large hands even while wearing riggers gloves against the heat.

I planished the weld to remove the shrinkage and ground and sanded it smooth.

Got it held in place with some screws while I continue on making the rest of the door jam. Later on I will add a floating nut plate inside for both door strikers to bolt to.

Video update.